Industrial Insulation

Industrial premises of all forms require insulation. And whether property owners undertake insulation to comply with building regulations or to control the temperature of their facilities, they are going to save money either way. But many business owners are confused about which industrial insulation product will work best.

For industrial properties, the answer is almost always spray foam insulation. Why? Because spray foam can offer up to 50% more energy savings than traditional insulation which is also far less effective in creating an air barrier than foam spray.

Not only this, but spray foam can be more flexible – it can be applied to virtually any surface, is easy to install and, for large industrial buildings, its expansion properties are impressive. Spray foam can expand up to 100 times its original size to make sure every cavity is filled – even in hard-to-reach spaces.

And because it can be used for a variety of applications around the industrial building, it is the endlessly flexible insulation option too. You won’t need to invest in different types of insulation for different areas of the building or for different assets within it – spray foam insulation will work.

But if you’re new to spray foam insulation, or want more information about its industrial insulation benefits, let’s dive into the details.

What's on this page?

What is Industrial Insulation?

Industrial insulation is the application of any form of insulation to a commercial building. But not all forms of insulation are either suitable or practical for the larger scale buildings that usually form part of an industrial unit or complex.

For most purposes, polyurethane spray foam insulation is the best insulation to apply to commercial buildings especially as many of these buildings are constructed using metal materials. And it’s likely that insulation was not a priority during the initial build.

The application of spray foam for industrial insulation, in both new and older buildings, can significantly improve temperature regulation, soundproofing, the air quality, and can help achieve higher fire safety standards – the decrease in energy costs doesn’t hurt either.

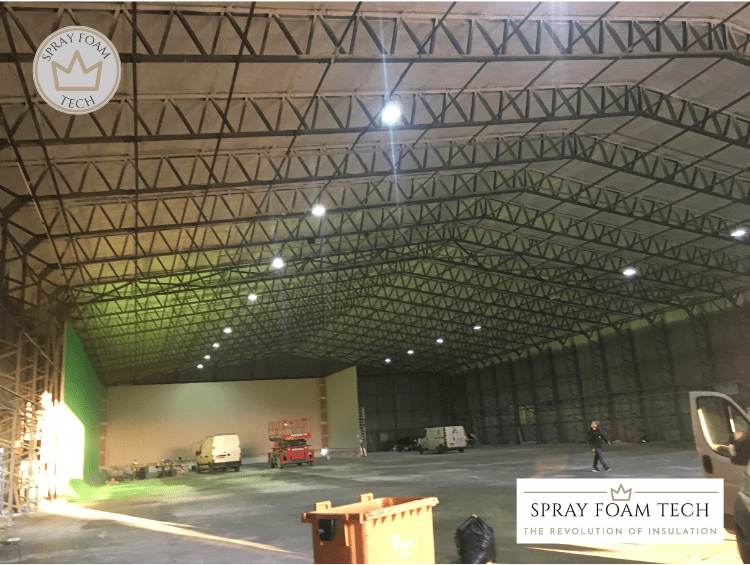

Industrial foam insulation is sprayed on the interior of steel or aluminium structures, including industrial ceilings or to seal asbestos roof panels. And with a thickness of as little as 50mm, you can lower the U-value of your commercial building significantly.

Now let’s look at the options on offer for industrial building insulation.

Featured Projects

Types of Industrial Insulation

There are many factors to consider when choosing insulation for your commercial property as most industrial insulation specialists would tell you. But the most important decision is choosing the right type of types of insulation for the application and making sure the insulation type has the thickness required for the best insulation performance.

Some forms of insulation that might be used in commercial properties are often the same as you might find used in residential properties. And there are four main types:

Loose Fill – this type of insulation is made from loose fibres. It’s sometimes referred to as ‘blown or blown-in’ insulation and is widely available in cellulose or fibreglass insulation products. It’s most often used to fill gaps in existing insulation, such as in wall cavities.

Batt and roll insulation – This is the type of insulation often used in residential properties. They either come in pre-cut pieces (batt) or on a roll. As with loose fill, it is often made of fibreglass or mineral wool.

Reflective Insulation or Radiant Barriers – As the name implies, these are designed to limit thermal radiation from transferring heat. It’s made using a reflective material facing, usually aluminium foil, with sometimes an added layer of internal insulation such as polyethylene bubbles or cardboard.

Spray Foam Insulation – Spray foam is an industrial polyurethane foam that expands to create a monolithic layer across the surface it’s applied to. Unlike other types of insulation, it does not need to be joined and can be applied without leaving any voids, cavities, or gasps, between itself and the surface of the building. And for this reason, insulating with industrial polyurethane foam is the most effective and money-saving choice for commercial properties.

Benefits of Industrial Spray Foam Insulation

The benefits of using industrial foam insulation are many. The most important being the money saved through increasing your property’s energy efficiency. But let’s look at the other main benefits.

Reduce Fuel Costs

Because you’ll be plugging drafts through the application of the foam spray, as well as the higher thermal resistance the product offers, your energy or fuel costs could be reduced by up to 50%.

Better Temperature Control

Spray foam offers an effective way to regulate the temperature within your commercial building without the need to instal air conditioning or heating units which would drive your energy costs higher.

Improve Air Quality

Because closed cell spray foam offers a high level of density, it is virtually water resistant This means it significantly reduces condensation problems, repels mould and mildew spores and stops large-scale water ingress. It also reduces most pollutants from entering the building and so improves the internal working atmosphere.

The reverse is true too. So, if you’re working with harmful chemicals, it can stop them from polluting the surrounding atmosphere and enable you to retain tighter control of your air quality processing.

Improve Structural Integrity

For certain buildings, the rigidity of spray foam insulation can add a greater level of structural integrity to your commercial property. And it may also be used for asbestos encapsulation in older buildings. Industrial roof insulation is also a good choice for retrofitting agricultural buildings and can help firm up existing structures.

Spray Foam Insulation Industrial Applications

Spray foam insulation industrial applications have endless commercial uses and can be used on almost any surface. But to give you some idea of its most popular industrial uses you’ll find it in:

- factories

- warehouses

- exhibition halls

- showrooms

- shipping containers

- vessels

- agricultural buildings

- football stadiums

- offices

- industrial units

- vans

- retail units

- municipal/charitable/ religious buildings

To be honest, there are very few industrial buildings that couldn’t be improved by adding spray foam insulation.

Conclusion

Engaging industrial insulation services is really a no-brainer for many companies who need to improve their energy efficiency. And let’s face it, most do.

Hiring skilled and experienced industrial insulation companies and contractors is a must, though, to ensure your investment pays off.

But for the most versatile, flexible, and thermally effective option, industrial spray foam insulation is going to be the right fit.