What Measures Are Required Prior to Spray Foam Applications?

What's on this page?

Heat and Moisture Transport

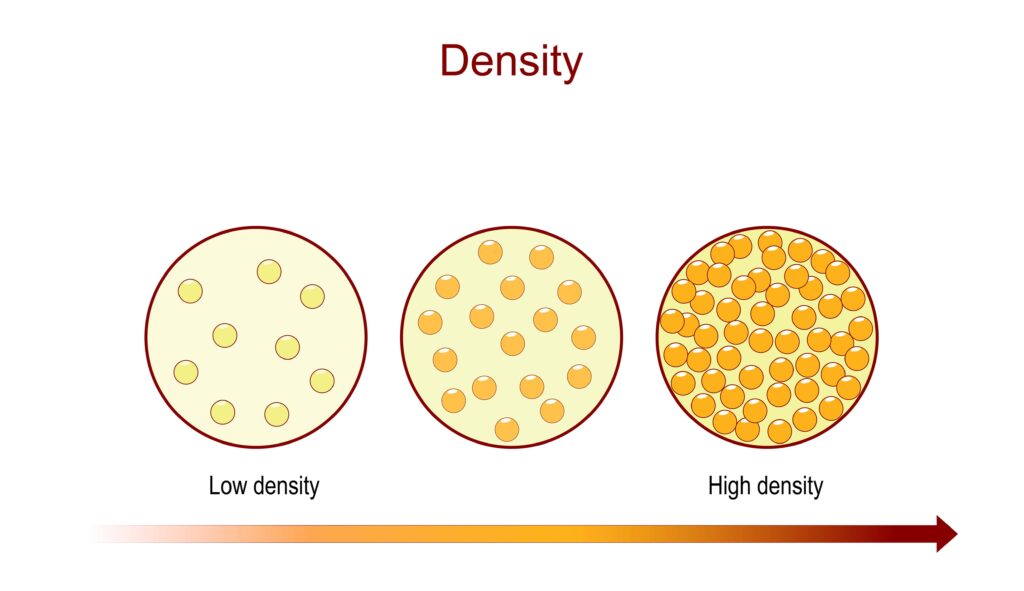

Density

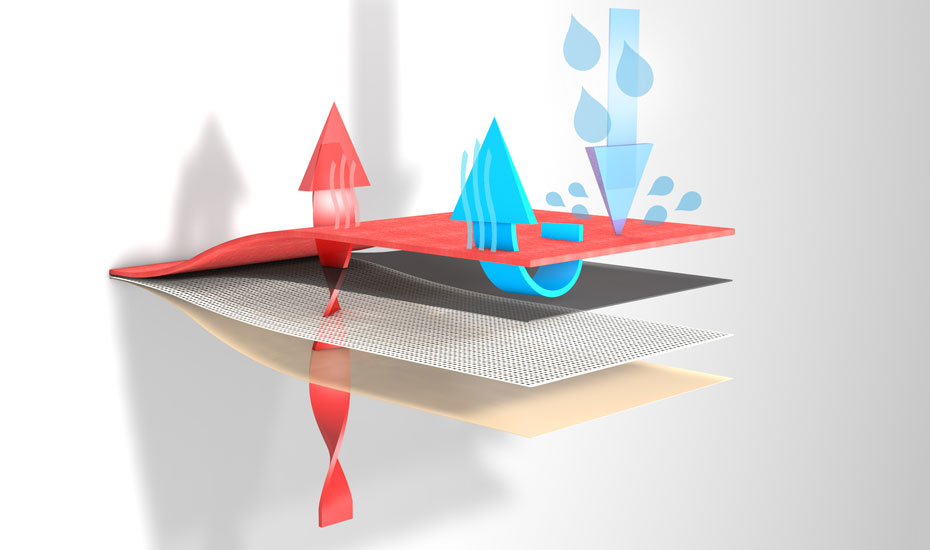

Permeability / Vapour resistance

Thermal Conductivity (K Value / Lambda Value)

Material | Lambda Value |

Open cell foam | 0.035W/mK |

Closed cell foam | 0.027W/mK |

Thermal Resistance (R Value)

Thermal Transmittance (U value)

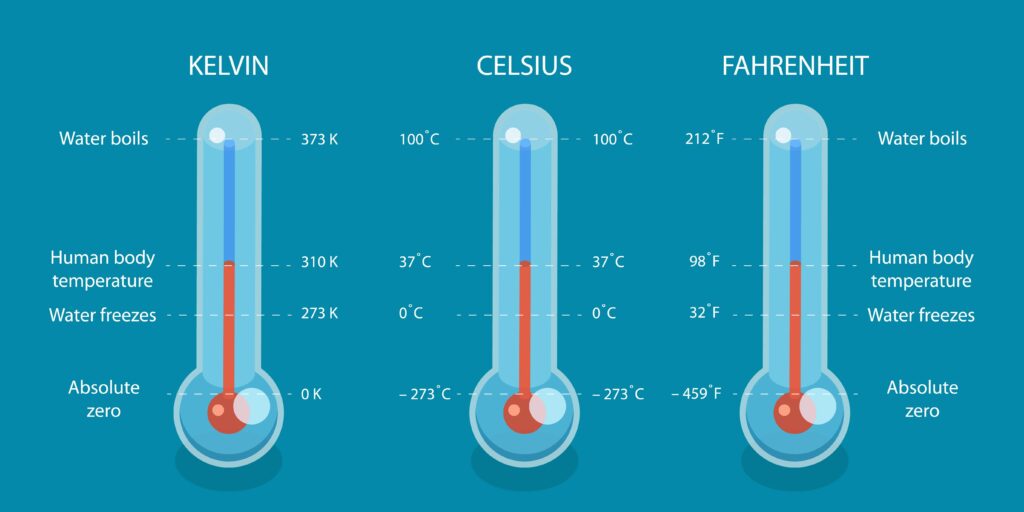

Thermodynamic temperature

Thermal Conduction

Thermal convection

Vapour convection

Vapour diffusion

Airtightness

Surface Condensation

Surface condensation occurs when moisture in the air comes into contact with a surface that is colder than the dew point temperature of the air. This can lead to moisture accumulating on the surface, which can in turn lead to mould growth, corrosion, and other problems.

To prevent surface condensation from occurring, it is important to properly insulate surfaces and maintain a consistent indoor temperature. Spray foam insulation is an effective way to prevent surface condensation by creating a barrier between the cold surface and the warm, moist air.

At Spray Foam Tech, we use high-quality spray foam insulation to ensure that your property is protected from surface condensation. Surface condensation as well occurs when water vapour in the air comes in contact with a cold surface, such as a window or uninsulated wall. This can lead to the formation of water droplets on the surface, which can then lead to mould growth and other issues. To prevent surface condensation, it’s important to ensure that your building is properly insulated and that there are no cold spots where moisture can accumulate.

We prioritise the safety and satisfaction of our clients. This is why we utilise BuildDesk and WUFI software to ensure that our products are applied in a way that minimises the risk of condensation. By assessing the potential for condensation year-round, we can take preventative measures to avoid any issues that may arise.

Our accredited installers are highly trained and experienced, ensuring that our products are applied in accordance with the certification and parameters outlined in our calculations. By following these strict guidelines, we can guarantee that there is no risk of condensation when using our products and services.

We understand the importance of providing reliable and effective solutions to our clients, which is why we prioritise the use of advanced software and highly skilled installers. With Spray Foam Tech, you can have confidence in the quality of our products and the expertise of our team.

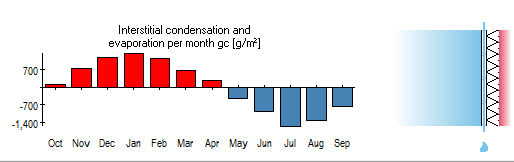

Interstitial Condensation

Interstitial condensation occurs when moisture in the air becomes trapped within the layers of a building’s structure. This can occur when warm, moist air from inside a building comes into contact with a cold surface, causing the moisture to condense and become trapped. Interstitial condensation can lead to rot, decay, and other structural damage. To prevent interstitial condensation, it is important to properly ventilate the building and use effective insulation.

Spray foam insulation is an effective way to prevent interstitial condensation by creating a barrier between the warm, moist air and the cold surface. At Spray Foam Tech, we use high-quality spray foam insulation to ensure that your building is protected from interstitial condensation.

Interstitial condensation, as well, occurs within the building’s insulation. This can happen when warm, moist air from inside the building permeates through the insulation and comes into contact with a cold surface, such as the outer layer of the insulation or the exterior wall. This can lead to moisture buildup within the insulation, which can then lead to mould growth and other issues. To prevent interstitial condensation, it’s important to use insulation materials that have a high resistance to moisture penetration.

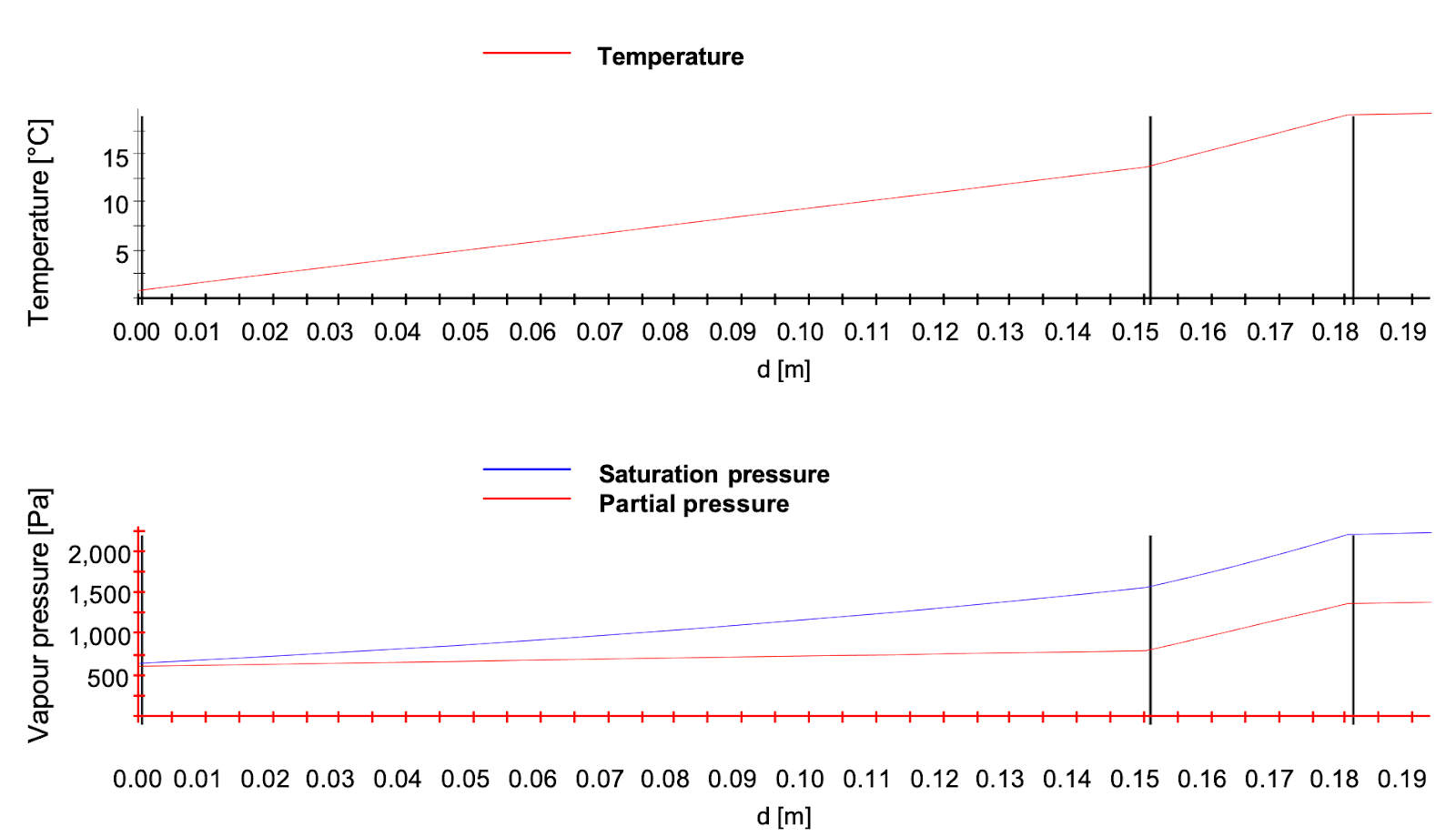

One key factor to consider when addressing both surface and interstitial condensation is partial pressure. Partial pressure is the pressure exerted by a single gas in a mixture of gases, such as the air inside and outside of a building. External and internal partial pressures are affected by factors such as temperature, humidity, and air flow. It’s important to understand how these factors can impact partial pressure and moisture buildup within your building’s insulation.

In order to properly address moisture buildup and prevent issues such as mould and mildew, it’s essential to work with a professional insulation contractor who has experience in identifying and addressing these issues. A professional contractor can assess your building’s insulation needs and recommend the best materials and techniques to ensure that your building remains dry and free from moisture-related issues.

At Spray Foam Tech, we specialise in providing high-quality insulation services that are designed to prevent moisture buildup and other common insulation-related issues. Our team of experienced professionals can assess your building’s insulation needs and recommend the best solutions to help you maintain a healthy, dry, and comfortable indoor environment. Contact us today to learn more about our insulation services and how we can help you protect your investment.

Partial Pressure

Partial pressure is a measure of the pressure that a gas exerts within a mixture of gases. In the context of building insulation, partial pressure is important because it can affect the movement of moisture through the insulation material. External and internal partial pressure can be affected by external temperature, humidity levels, and other factors.

At Spray Foam Tech, we use BS EN ISO standards to measure external and internal partial pressure and ensure that our insulation products are effective at preventing moisture buildup and other problems.

External Temperature & Internal Temperature

External and Internal temperature is an important factor to consider when installing building insulation. External temperature can affect the rate at which heat is transferred through the insulation material, which can in turn affect the temperature and humidity levels inside the building.

We use BS EN ISO standards to measure external & Internal temperature and ensure that our insulation products are effective at maintaining a comfortable indoor environment.

Overall, we are committed to providing high-quality insulation solutions that protect your property from surface and interstitial condensation, and other moisture-related problems. Our products are designed to meet BS EN ISO standards for measuring partial pressure and external temperature, ensuring that your property is properly insulated and protected from the elements.

Dew Point

Dew point is a crucial parameter used to measure the moisture content in the air. It is the temperature at which the air becomes saturated with water vapour and starts to condense into liquid. Knowing the dew point is essential in various applications to prevent moisture-related problems and ensure optimal air quality.

At Spray Foam Tech, we understand the importance of monitoring the dew point, which is why we use the latest technology to measure it accurately. We use Buildesk, a software designed specifically for the UK, to measure the dew point temperature. This enables us to maintain the appropriate moisture levels and ensure that our work is of the highest quality.

The importance of monitoring the dew point lies in its ability to prevent moisture-related problems. High levels of moisture in the air can lead to mould growth, corrosion, and condensation, causing damage to buildings, equipment, and products. By monitoring the dew point, one can maintain the appropriate moisture levels and prevent such problems.

In industrial settings, measuring the dew point is crucial in compressed air systems. Compressed air must be kept dry to prevent damage to the equipment and ensure its efficient operation. The dew point of the compressed air must be maintained below a certain level depending on the type of equipment and application.

In construction and building maintenance, the dew point is essential in preventing structural damage and maintaining a healthy environment. Moisture in walls, ceilings, and floors can lead to mould growth, weakening of the structure, and health issues. By measuring the dew point of these surfaces, one can ensure that they are not too moist and prevent these problems.

In HVAC systems, the dew point is used to determine the optimal humidity levels for comfort and energy efficiency. By maintaining the appropriate dew point levels, one can ensure that the air quality is optimal and prevent health issues such as dry skin, allergies, and respiratory problems.

Understanding the dew point is essential in various applications to prevent moisture-related problems and ensure optimal air quality. Measuring the dew point using Buildesk software, as we do at Spray Foam Tech, is crucial in maintaining the appropriate moisture levels in industrial, construction, and HVAC systems. By monitoring the dew point, one can ensure a healthy and safe environment while preventing damage to buildings, equipment, and products.